Components

Whether the best explosion protection solution is suppression, venting or isolation, IEP Technologies offers the right products to meet your needs. Our system components undergo rigorous third-party testing to receive the approvals required by, for example, ATEX and NFPA. As each explosion protection threat is unique, we offer different types of explosion detectors, controls units and suppressors to tailor the design of the protection system to each individual application.

Control Units

-

Single-Zone (EX-100.1/200) and Multi-Zone (EX-8000) Control Unit

A control unit is microprocessor-based and has both control and verification functions. It is comprised of control and battery charging circuits, a power supply and front panel which includes control and indication functions visible through a scratch-resistant window. The unit is packaged in an enclosure which is designed to provide superior dust contamination and weather resistance. Terminal access has been carefully designed for ease of installation.

Any signals emerging from the explosion pressure or flame sensors are recorded, tested and evaluated by the control unit. The monitoring and activation lines are continuously checked for wire breakage, earth fault and short circuit. Additionally, an automatic self-test system ensures that all important functions of the control unit are verified electronically. These control units provide both trouble relay contacts for process interlocking, and alarm relay contacts for notification should a system actuation occur.

Detection

-

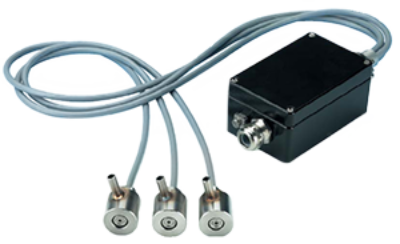

SmartDS Dynamic Detection system

Dynamic measuring cells in the detector sense changes in pressure. Once pre-programmed pressure values are exceeded, the detector reacts within microseconds to raise an alarm. The MEX Detector has up to two ceramic sensors within a single, solid housing. This is the only detector with algorithmic-based output and decision-making logic based on full-scale explosion tests, expert knowledge and application experience. The output and decision logic provides the highest detection security by evaluating the difference between an explosion pressure rise and process pressure variations. The ceramic cell sensors make the detector more resistant to mechanical damage and corrosive dusts, gases and liquids. By means of a field terminal box (“FAB”) the MEX Detector can be connected to various control units.

Competitive advantages of the MEX Detector include:

Dynamic pressure detection based on the characteristic temporal profile of pressure increase associated with confined explosion occurrences. This significantly increases false alarm immunity as well as detection security.

Utilizes two pressure-sensing cells to increase detection security and redundancy.

Field-programmable unit to accommodate a wide range of hazard and process conditions. Also features a history buffer for programming set point during commissioning as well as diagnosis of incident after actuation.

-

Static Pressure Detector

Static pressure detectors are used in stable processes that only have one threshold (at which point the detector is activated). The detector is field-adjustable as well as FM approved. These detectors are typically mounted in pairs with vibration isolation standoffs to minimize the risk of false alarms due to operator errors. Static pressure detectors are dependable, reliable and have a proven track record.

-

UV-IR / UV-IR-HD

The FlameSpec UV-IR and UV-IR-HD flame detectors provide ultra-fast response, high performance and reliable detection of a large variety of fires including hydrocarbon fires (visible and non-visible), hydrogen and methane/hydrogen mixed fires. These flame detectors are designed to

respond in milliseconds to the ultraviolet and infrared light emitted from a flame source. -

Infrared and Ultraviolet Infrared Detectors

Optical detectors include infrared (“IR”) and ultraviolet infrared (“UV-IR”) detectors which are integrated in explosion prevention systems for specific applications. The IR detector is typically used in interconnected duct work for dust-handling systems. The UV-IR detector is used in combustible gas or vapor protection systems such as aerosol fill rooms and chemical storage rooms.

Suppressors

-

eSUPPRESSOR™

The IEP Technologies eSUPPRESSOR™ is a high-rate discharge suppressor used for explosion suppression and isolation systems. Its electro-mechanical operation is unique to the industry, as no pyrotechnic devices are required for activation. The eSUPPRESSOR has standard features that include pressure monitoring, lock out-tag out capability and LED indication of device status.

A key benefit is that all the safety functions are fully monitored, which is not possible for any device employing pyrotechnic actuators. The eSUPPRESSOR design and manufacture has SIL2 third party certification.

Upon detection of an explosion event, the Explosion Protection Control Unit sends an actuation signal to the eSUPPRESSOR valve mechanism. The highly specified trigger mechanism allows the valve flap to open extremely rapidly (less than 10ms), which allows the suppressant to be discharged through the nozzle system into the protected volume.

-

PistonFire II

The PistonFire suppression tank consists of a pressurized extinguishing agent storage tank and a valve body with a dust explosion-proof, weather-resistant housing in accordance with the requirements of the National Electrical Manufacture’s Association ("NEMA"). The NEMA-compliant housing houses the actuator mechanism, pressure switch, pressure gauge, fill valve, OSHA control switch, and field wiring connections. With a screwed-on cover and a quick-release connector for easy connection to the field wiring, the NEMA-compliant housing is completely sealed. When an incipient explosion is detected, the suppression container receives a switching signal. The actuating mechanism initiates the rapid release of the pressurized extinguishing agent from dry chemicals into the protected area within milliseconds.

The competitive advantages include:

DOT and TC approved - pressurized in the factory, leak tested and transported to the point of use, versus on-site pressurization and leak testing

Monitored and interlocked low pressure switch according to the latest version of NFPA 69

Non-explosive initial charges, safe to use (no ATF or UN restrictions)

OSHA locking plate according to the latest version of NFPA 69

Nozzles can be tested in the assembled state (NFPA 69), against dismantling or opening of the container by external companies -

EHRD II Suppressors

The IEP Technologies EHRD II is a high-rate discharge suppressor used for explosion suppression and isolation systems. Upon detection of an explosion event, the Explosion Protection Control Unit sends an actuation signal to the EHRD II valve mechanism. The valve opens extremely rapidly (less than 10ms), which allows the suppressant to be discharged through the nozzle system into the protected vessel to mitigate potential damage caused by the detected incipient explosion.

-

PHRD Suppressor

These suppressors are used for explosion suppression of gases, solvent vapours and combustible dusts. The suppressors deliver high rates of suppressant that quench an explosion flame in its early stages, thus preventing a pressure rise from reaching dangerous proportions.

A cylindrical alloy steel container filled with 3kg, 4kg or 16kg of powder suppressant and pressurised to 60 bar (880 psi) with dry nitrogen. Inside the flange is a hinged flap supported by a beam which is kept closed by a latch. Two piston, non-explosive protractor operated actuators are used to initiate opening. When the actuators are activated by means of an electrical impulse from the associated control unit, pistons move the latch, which allows the flap to open. The nitrogen then expels the suppressant at high rate through the spreader assembly into the protected volume.

Isolation Devices

-

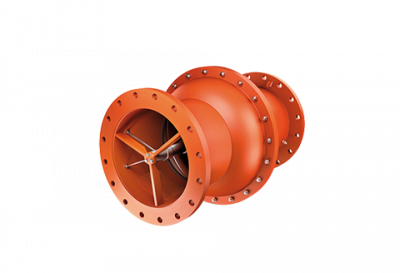

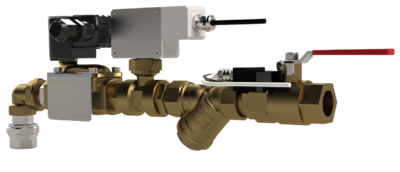

High-Speed Isolation Valve

The High-Speed Isolation Valve provides a solution for vital explosion isolation applications. It operates in milliseconds to provide a mechanical barrier within a pipeline. The High-Speed Isolation Valve has a stainless-steel body incorporating a fully ported stainless-steel valve gate. The valve is designed to withstand a 150 Psi pressure wave from a deflagration without deformation. Closure is achieved in milliseconds by rapidly discharging nitrogen into a piston actuator. The nitrogen is supplied by an IEP Technologies High-Rate Discharge Bottle. Detection is typically provided by an IEP Technologies explosion pressure detector. The detector is monitored by an IEP Technologies control unit which provides supervision, alarm, system actuation, and process shutdown. Typical applications for the valve include explosion isolation on dust collectors, mills, fans, vapor recovery lines, dryers, and other interconnected process equipment.

-

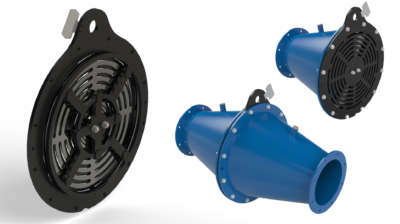

IsoFlap™ Passive Isolation Valve

For process equipment mounted outside or close to an outside wall, explosion relief venting is a viable protection method. However, in order to protect the upstream equipment, it is vital that the protection method includes a means to mitigate the propagation of flame and burning materials back upstream. This can be achieved by either using an active isolation system (chemical or mechanical) or by using a passive isolation valve. The passive explosion isolation valve is a self-actuating device, which provides a mechanical barrier to mitigate the propagation of flame and burning materials to upstream equipment. The passive isolation valve provides features unique to this style of valve, including an Accumulation Sensor, Wear Sensor, and Interface Panel.

-

IsoDisc™ Passive Isolation Valve

The IEP Technologies range of passive isolation devices type IsoDiscTM is a cost-effective and reliable explosion isolation solution that mitigates explosion propagation risks to upstream equipment or flame and pressure transmission to the environment. These passive isolation solutions are effective, self-actuating devices providing inlet explosion isolation to protected vessels handling combustible dust, such as air aspiration inlets of mills or clean air pipe ducting connected to equipment where explosive dust is handled.

-

VENTEX Passive Isolation - Float Valve

For process equipment mounted outside or close to an outside wall, explosion relief venting is a viable protection method. However, in order to protect the upstream equipment, it is vital that the protection method includes a means to mitigate the propagation of flame and burning materials back upstream. This can be achieved by either using an active isolation system (chemical or mechanical) or by using a passive isolation valve. The passive explosion isolation valve is a self-actuating device, which provides a mechanical barrier to mitigate the propagation of flame and burning materials to upstream equipment.

Vents & Flameless Vents

-

IVE Flameless Explosion Vent

The IVE Flameless Explosion Vent provides an explosion protection solution for process vessels, especially bucket elevators, which are located inside a building or areas where standard explosion venting cannot be safely employed. For these applications, flameless explosion vents may be the best protection solution. When an explosion occurs, the venting device opens and vents the explosion pressure and flame through a flame arrester, thereby cooling the hot gases and quenching the flame. The IVE utilizes a stainless steel explosion relief vent and flame arresting mesh enclosed in a durable carbon steel coated frame. The integrated vent burst detection sensor allows plant personnel to respond accordingly in the event of an explosion within the protected application.

-

IV8 Flameless Explosion Vent

The IV8 Flameless Explosion vent provides an explosion protection solution for process vessels that are located inside a building or areas where standard explosion venting cannot be safely employed. For these applications, flameless explosion vents may be the best protection solution. When an explosion occurs, the venting device opens and vents the explosion pressure and flame through a flame arrester, thereby cooling the hot gases and quenching the flame. The IV8 utilizes a stainless steel explosion relief vent and flame-arresting mesh enclosed in a durable carbon steel coated frame. The integrated vent burst detection sensor allows plant personnel to respond accordingly in the event of an explosion within the protected application.

-

EVN Flameless Explosion Vent

Many process vessels are located inside a building or another area where standard explosion venting cannot safely be employed. For these applications, flameless explosion vents may be the best protection solution. The EVN flameless vent consists of a venting device with an integrated flame arrester. When an explosion occurs, the venting device opens and directs the vented explosion through the flame arrester, where gases are cooled as they pass through the flame arrester material thus preventing flames from being expelled to the surrounding areas. The integrated electronic controls keep plant personnel informed of the status of the system.

-

BESS-eX® Vents for Battery Energy Storage Applications

Typically the most cost-effective option in terms of installation and maintenance, IEP Technologies’ Passive Protection devices take the form of explosion relief vent panels which safely divert the deflagration to a safe place (atmosphere) and in doing so prevent the rapidly developing explosion pressure from causing container rupture, structural damage, and possible injuries to personnel. Vent sizing is based on a number of different factors, including explosivity characteristics of the vapors that may be off-gassed from the specific type of batteries, container strength (including door latches and hinges), opening pressure of the vent panels, and free area atop the storage unit for vent panels to reside. A qualified professional should be used when determining the size and quantity of vent panels to be used for BESS units and various designs, sizes, and profiles are available to suit all installations and locations, including “flameless venting” devices if the explosion cannot be safely vented to atmosphere.

-

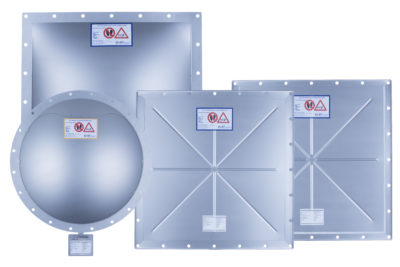

Explosion Vents

IEP Technologies Explosion Vent Panels are designed to minimize damage to process vessels, ducts, and other industrial structures in the event of a deflagration involving combustible materials. They are relief devices designed to rupture at a predetermined pressure, allowing the fireball and pressure from a deflagration to vent into a safe area. These highly efficient vent panels fit into the walls and sometimes the roof of a process vessel, and are available in a variety of sizes, configurations, ratings, and materials to suit specific applications. Styles include rectangular or round, domed or flat vent panels. Options include insulated vent panels and burst sensors for an indication that a vent panel has ruptured.

Spark Detection

-

SD300-EX/SDF300-EX Spark Detectors

The Atexon® SD300-EX (standard) and SDF300-EX (IR only) Spark Detectors are designed to detect ignition sources such as hot particles and burning embers, in a conveying path such as a duct, chute, or mechanical conveyor, and signal the Atexon Spark Detection System to initiate a water spray, helping prevent the ignition source from starting a fire or explosion.

-

EXT 11 / EXT 12 / EXT 22 Extinguishing Units

Atexon extinguishing units help prevent dust explosions and fires by automatically extinguishing detected sparks. The EXT11, EXT12, and EXT22 extinguishing units have been designed for pneumatic transport duct systems moving material at very high speeds. Once detection occurs, a small amount of water is sprayed into the process, extinguishing the hazard without damaging the protected processing equipment. Extinguishing stops automatically a few seconds after the last spark has been detected.

-

AXN4 / AXN18 / AXN18R Control Panels

The Atexon®spark detection and extinguishing control panel comes equipped with a user-friendly interface, large LCD display, Ethernet-based remote user communication, and enough memory to log thousands of extinguishing events. Furthermore, the use of serial bus communication throughout the ATEXON®spark detection and extinguishing system reduces both cabling to the AXN control panel and associated installation costs.