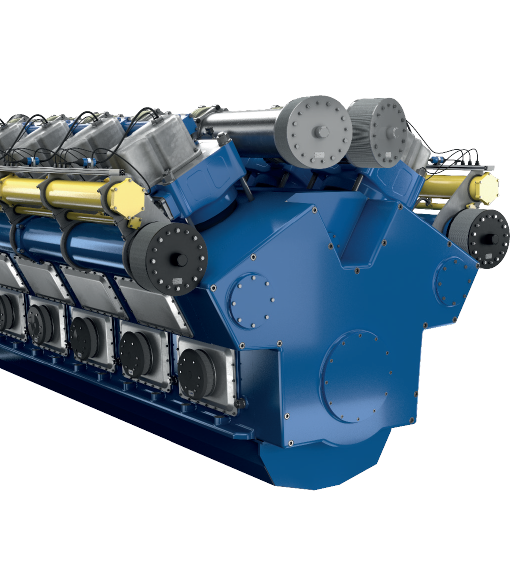

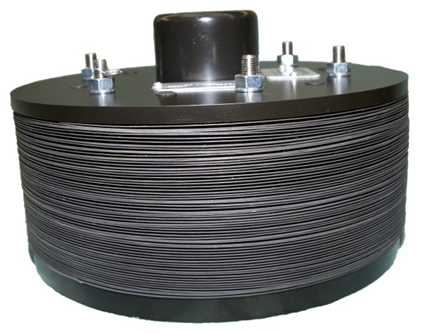

Explosion relief valves are reusable, flameless venting device, which are made for the protection of personnel and equipment in case of gas or oil-mist explosions. In the event of an explosion, the valve plate lifts up and relieves the overpressure through the integrated flame arrester, allowing pressure relief while stopping flame transmission. Immediately after the pressure event, the valve plate closes, allowing continual process operation.

Features

• ATEX and IACS certification

• Optimum protection for service personnel, engines and piping systems

• Flameless explosion relief

• No shut-down required after an explosion due to immediate re-closing

• Virtually maintenance free

• Flexibility in installation (can be located in any position)

• Designed opening pressure for each application

• Reliably opens over wide ranges of temperatures

• Function and opening pressure are tested on each relief valve (safety product)

EVT Relief Valve

For high pressure inputs, such as intake and exhaust manifolds, opening pressure typically above 2.0 bar

EVM Relief Valve

For low pressure inputs, such as exhaust and downstream piping, opening pressure as low as 0.2 bar

EVO Relief Valve

For ambient to low pressure engine crankcase combustible oil-mist, opening pressure 0.05 bar