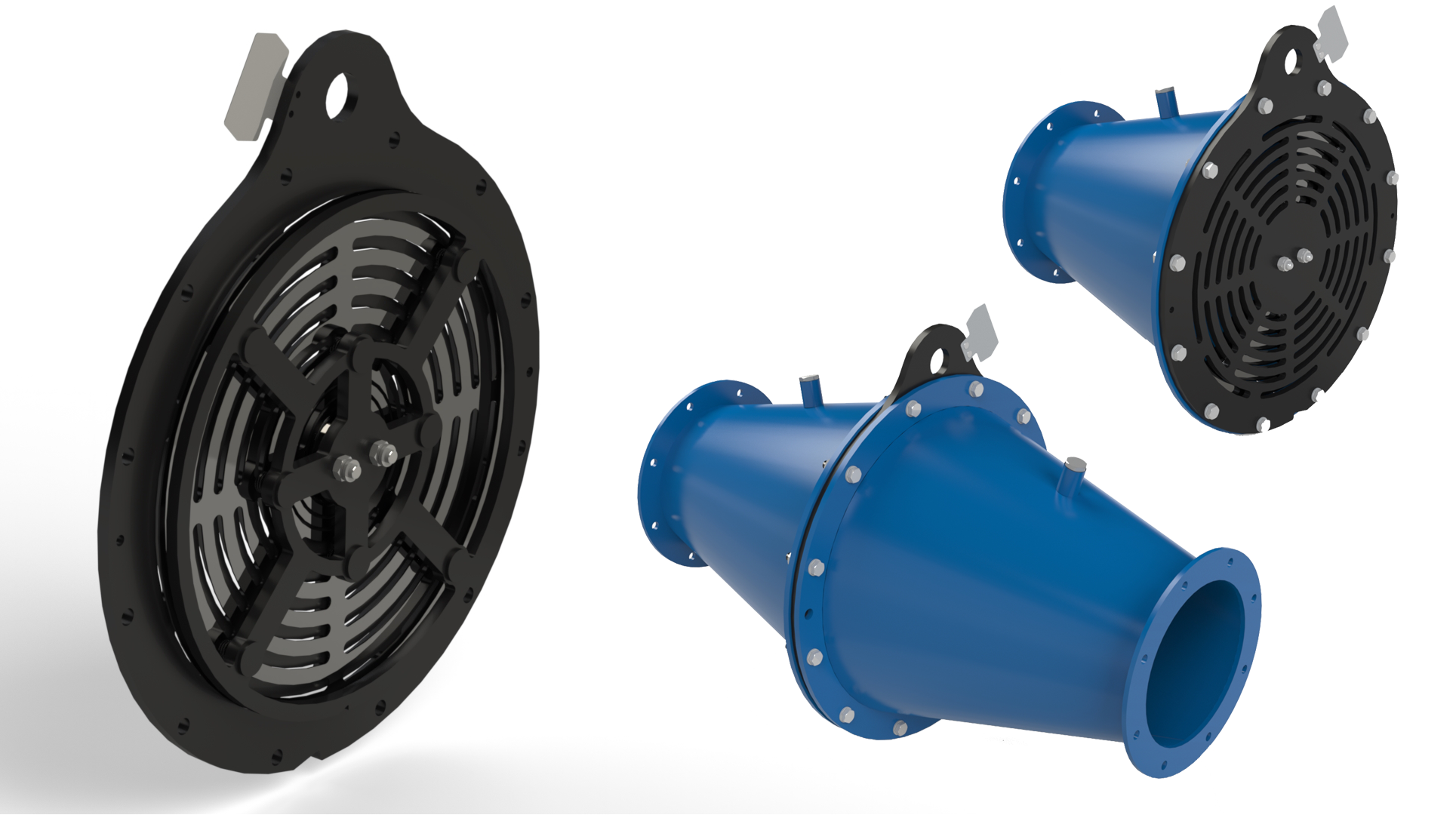

IsoDisc™ Passive Isolation Device

The IEP Technologies range of passive isolation devices type IsoDiscTM is cost-effective and reliable explosion isolation solution that mitigates explosion propagation risks to upstream equipment or flame and pressure transmission to the environment. These passive isolation solutions are effective, self-actuating devices providing inlet explosion isolation to protected vessels handling combustible dust such as air aspiration inlets of mills or clean air pipe ducting connected to equipment where explosive dust is handled.

The IsoDisc is a passive explosion isolation option according to EN15089. Per default, the valve is closed. During normal process operation, the IsoDisc valve plate is held open by the process airflow. In the event of an explosion on the downstream side of the process, the IsoDisc closes and isolates the upstream side of the process, mitigating the propagation of flame and pressure to the upstream equipment or to the environment.

The IsoDisc which can be mounted directly within process piping consists of a valve seat, valve guard, valve plate, and springs. Additionally, an optional adapter is available.

The IsoDisc version is 3rd party certified as a protective system according to EU directive 2014/34/EU (ATEX Directive) and is approved for the isolation of dust explosions. The IsoDisc with housing is equipped with a pipe adapter and can be directly installed in the piping. The IsoDisc with housing features durable carbon steel or stainless-steel valve housing and valve internals. The valve plate is made of high-quality steel alloy.

When applying explosion protection methods such as venting, flameless venting, or suppression, it is also necessary to reduce the risk of flame and explosion pressure transmission to interconnected vessels or the environment. The IEP Technologies IsoDisc offers a cost-effective, self-actuating, and efficient solution to mitigate the risk of explosion propagation. Typical applications for the IEP Technologies IsoDisc include explosion isolation of air aspiration inlets of mills and silos or clean air pipe ducting connected to equipment where explosive dust is handled.