Gaskets

All discs are supplied with "factory-installed" integrated flange gaskets. The standard material is EPDM and can be used from -40 °C to +120 °C. As an alternative the following standard materials are available:

White FDA Silicone - 50 °C to +200 °C

Klinger - 100 °C to +400 °C

Ceramic -100°C to +900 °C

Other materials can be supplied on request

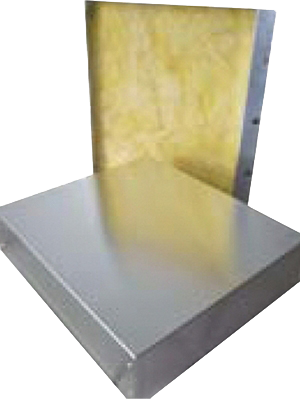

Insulation

Insulation consists of a fire-proof mineral wool according to DIN 1259. The insulation is directly mounted to the "vent- side" of the explosion vent and is protected by a light-weight aluminium cover with a water-tight seal. It is secured to the disc to prevent it from flying away during venting. BRILEX insulation does not have any affect on the venting relief capability or efficiency. This has been proved by notified bodies in many dynamic explosion tests. Optional insulation thickness can be supplied to meet the customer's specifications.

Insulated BRILEX - KE.

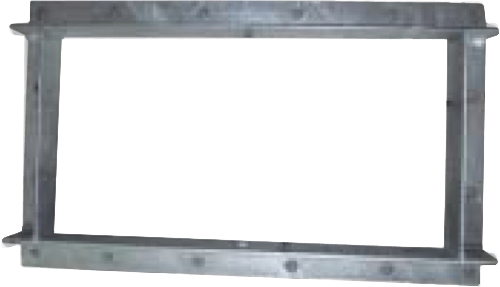

Mounting Frames

The necessary outlet flange for types GE / KE can also be supplied. The following material is available: Zinc plated carbon steel or stainless steel.

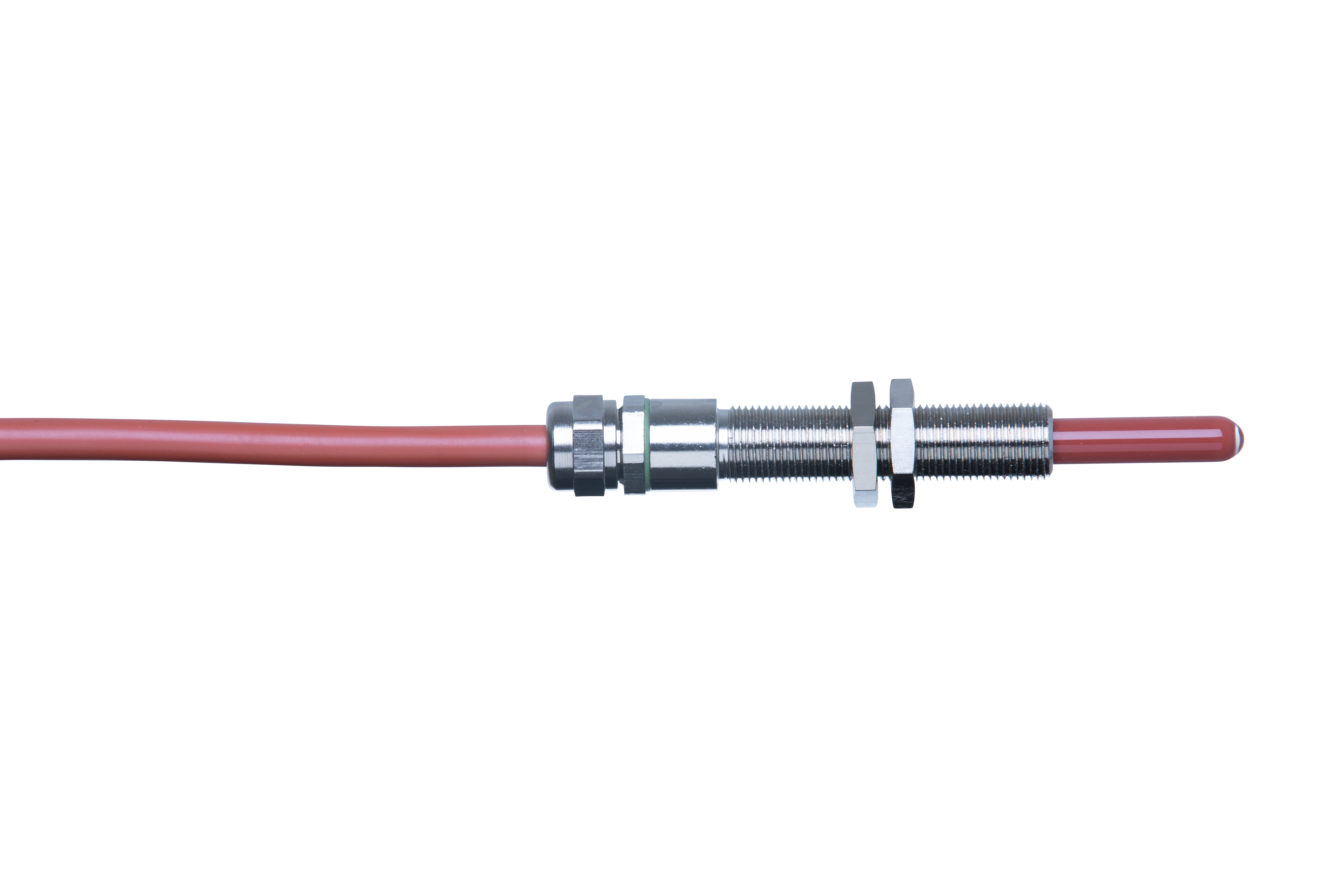

Burst Sensor SE-HT

To monitor an explosion vent installation a burst sensor type SE-HT can be installed. The sensor signals the opening of the vent panel for operator alert and also shut down interlocked equipment such as fans or rotary valves. Burst sensors are installed separately just above the explosion vent. This enables burst sensors to be easily adapted to existing installations. The SE-HT sensor is suitable for use at high temperatures as well as applications within the food industry.

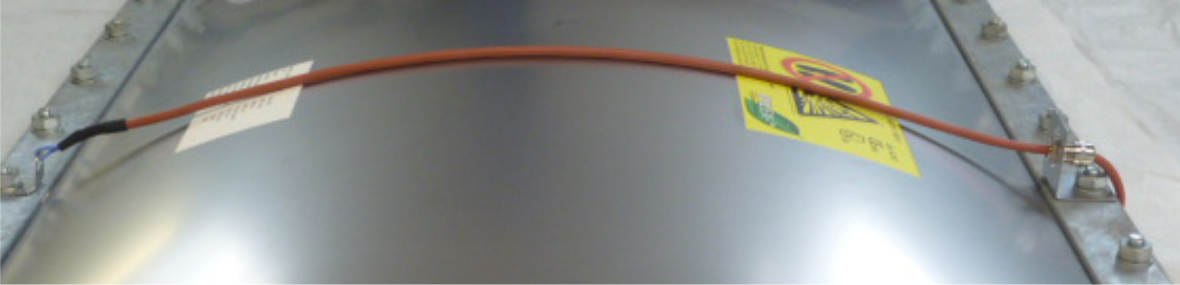

Burst Sensor SE - WIRE

The cable loop is broken when the explosion vent is opened. It results in the electric circuit interruption and a continuous, highly resistant signal is generated. The signal communicates explosion and immediate notification to personnel.