Explosion Diverter

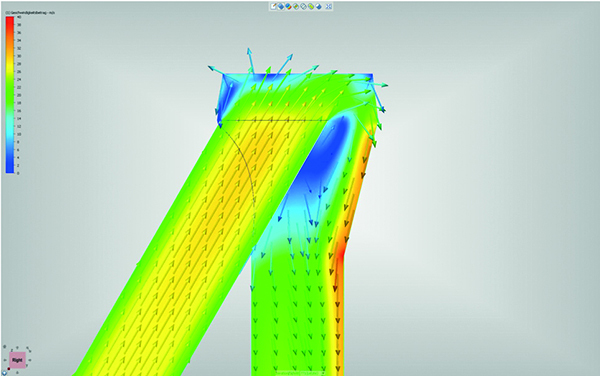

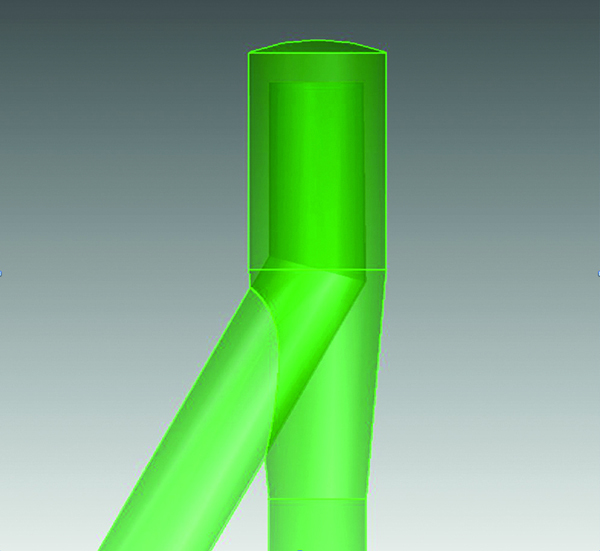

Explosion diverters were probably the first method employed to decouple dust explosions. The advantage of this method was always that it provided protection in both directions as it allowed pressure to be reliably decoupled at the explosion diverter, irrespective of whether the explosions came from the extractor or filter sides.

DIN EN 16020:2011

But the method wasn't very effective when it came to the suppression of flames, and spreading flames facilitate the propagation of explosions and often cause serious damage. The method also produces massive pressure losses in the affected systems, which also severely restricts the widespread use of such diverters.

But DIN EN 16020:2011 has now created a way of using explosion diverters safely. The testing procedures that it specifies with the design regulations and the detailed catalogue of requirements that it contains clearly set out the demands that such diverters must satisfy, if they are to be used in protective systems.

The right explosion vent

It's important for explosion diverters that the mechanical integrity of the fitted explosion vent has been certified accordingly. The explosion vent must be able to withstand the extreme conditions caused by the progress of the explosion in the explosion diverter.

BRILEX - GE, a rectangular explosion vent with specially shaped curvature that is resistant to vacuums and therefore delivers sufficient stability, is suitable for such applications. The explosion vent withstands severe pressure cycles without limit while providing reliable protection.