Battery Energy Storage Systems (BESS) represent a significant component supporting the shift towards a more sustainable and green energy future for the planet. BESS units can be employed in a variety of situations, ranging from temporary, standby and off-grid applications to larger, fixed installations. They are designed to provide stored, renewably generated energy at times of high demand. However, along with the benefits which a BESS application can provide, there is a need to fully assess the risk of fire and explosion when utilizing these units to support “load managed” energy applications.

The leading cause of fire and explosion inside a BESS enclosures is the release and ignition of combustible vapors from an overheating battery. Several high profile incidents have gotten the attention of the industry and regulators, prompting investigations and the development of safety standards to provide protection within this relatively new industry.

NFPA 855 [*footnote 1], the Standard for the Installation of Stationary Energy Storage Systems, calls for explosion control in the form of either explosion prevention in accordance with NFPA 69 [*footnote 2] or deflagration venting in accordance with NFPA 68 [*footnote 3]. Having multiple levels of explosion control inherently makes the installation safe therefore some jurisdictions require both preventative measures as well as the installation of explosion vents. Insurance companies are also reviewing the risk within these applications and underwriters may also require multiple levels of protection even if local regulations have not yet been developed.

Typically, the most cost-effective option in terms of installation and maintenance, IEP Technologies’ Passive Protection devices include explosion relief vent panels that open in the event of an explosion, relieving the pressure within the BESS unit and directing the pressure and flame to a safe area. In doing so, prevent the rapidly developing explosion pressure from causing BESS enclosure/container to suffer structural damage or even rupture along with possible injuries to personnel.

The questions most commonly raised when a BESS manufacturer needs to provide protections for their product usually relate to the enclosure construction, vent panel selection and sizing, and do they require insulation on the panel itself.

[*footnote 1] - National Fire Protection Association (NFPA) 855-2020: Standard for The Installation Of Stationary Energy Storage Systems.

[*footnote 2] - National Fire Protection Association (NFPA) 69-2019: Standard on Explosion Prevention Systems.

[*footnote 3] - National Fire Protection Association (NFPA) 68-2018: Standard on Explosion Protection by Deflagration Venting.

Why is determining the storage container strength important?

Determining the container strength is vital in the design of a suitable venting solution since a proper deflagration vent must be designed to operate and relieve the pressure increase from an explosion below the point at which the container will rupture.

The enclosure strength (Pes)) is defined in NFPA 68 as up to two-thirds of the ultimate strength for low strength enclosures, while for high strength enclosures the enclosure design pressure sufficient to resist is reduced pressure (Pred)). Pred is the maximum pressure developed in a vented enclosure during a vented deflagration (NFPA 68). Some BESS storage containers are purpose-made, however, others used for BESS are modified shipping containers that were not designed to withstand pressure, so the BESS manufacturer may not necessarily know the enclosure strength. In such cases, to determine Pes, a structural analysis of the storage container needs to be conducted. IEP Technologies can work with you to obtain this critical variable which is the starting point needed to properly size the required deflagration vents.

What factors determine vent sizing and where is the best placement?

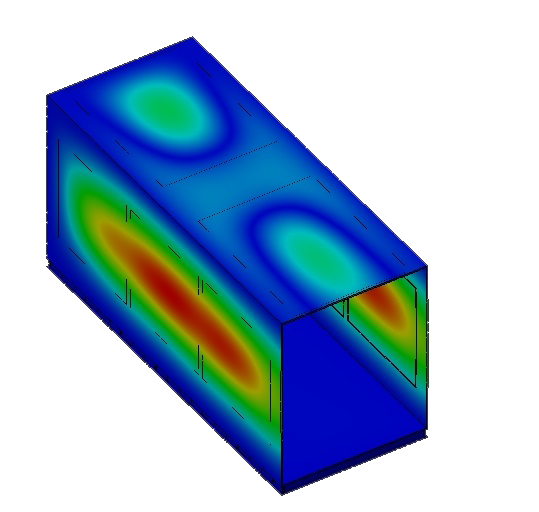

Vent sizing is based a number of different factors, including explosivity characteristics of the vapors that may be off-gassed from the specific type of batteries stored in the unit, container strength (including door latches and hinges), opening pressure of the vent panels, and free area atop the storage unit for vent panels to reside. The battery manufacturer will usually be able to provide the fundamental burning velocity of the off-gases if they performed the UL9540A test procedure. This fundamental burning velocity is a critical factor in properly sizing the deflagration panel. Mounting a venting panel on top of the enclosure is the preferred location since the potential fireball will discharge upwards which is usually a safe area. There is typically little unused space within BESS units therefore consideration should be given to any obstructions when designing the vent size and placement, including internal partitions. Vent panels are designed specifically to the applications so a qualified professional should be used when determining the size and quantity of vent panels to be used for BESS units. They may also utilize a CFD model to most accurately size the deflagration panels.

Is vent insulation needed?

This decision is often dependent on where the BESS unit will geographically be located along with the specific requirement of the equipment manufacturer. Proper vent design will include insulation that will meet the equipment manufactures requirements therefore it is important to know the thermal conductivity (R factor) of the BESS enclosure. IP rating for the vent panel should also be taken into consideration to ensure water and dust is kept out of the enclosure. IEP Technologies recommends an IP66 rating to meet even the most challenging of applications.

For over 60 years, IEP Technologies has offered leading-edge explosion protection solutions to customers worldwide and can assist with all stages of the selection process - from materials testing, passive and active explosion protection systems, spark detection and extinguishing, and ongoing service, training, and support. IEP Technologies forms part of the global HOERBIGER Safety Solutions network, with sales, service, and support centers located across North America, Europe, Latin America, the Middle East/Africa, and Asia/Pacific. To learn more about BESS explosion protection, or to find your local IEP sales, service, and support center, visit www.ieptechnologies.com or contact +1 855-793-8407.